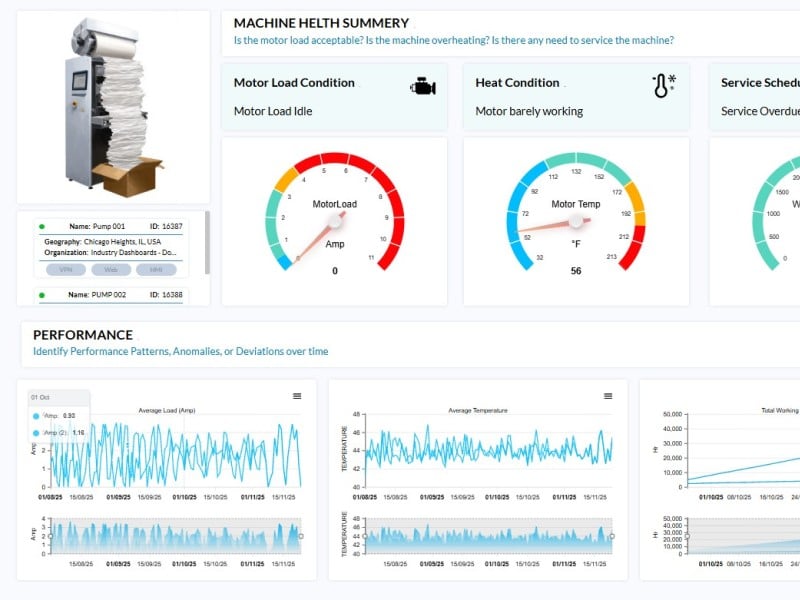

Provide a comprehensive view of a paper cushioning machine’s health, focusing primarily on motor condition and performance over time. The dashboard helps operators and maintenance personnel quickly identify signs of motor overheating, excessive load, and service needs. By tracking working hours and analyzing correlations between load, temperature, and usage, the system supports machine reliability, minimizes unplanned downtime, and optimizes the ‘Pay Per Use’ model by monitoring actual utilization.

Dashboard Overview

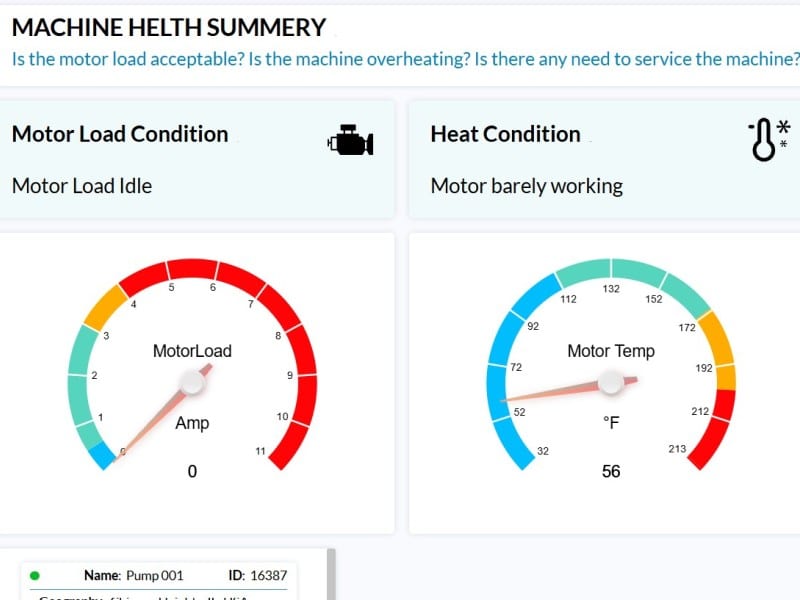

The dashboard opens with the MACHINE HEALTH SUMMARY, which displays three key diagnostic indicators:

1. Motor Load Condition: Evaluates the current motor load (Motor Load Idle) and provides an immediate answer to the question: “Is the motor load within acceptable limits?”

2. Heat Condition: Monitors the motor temperature and provides an assessment: “Is the machine overheating?” (Currently indicating “Motor barely working”).

3. Service Scheduler: Tracks total working hours and indicates if service is due (Currently showing “Service Overdue”).

The main view also features gauges displaying the real-time values for Motor Amp, Motor Temp, and Working Hours, allowing for a rapid assessment of the current operational state.

The PERFORMANCE section presents three line charts illustrating historical trends over time:

• Average Load: Shows the motor’s average load (in Amp) over the timeline.

• Average Temperature: Displays the average motor temperature over time.

• Total Working Hours: Tracks the cumulative growth in working hours.

The CORRELATIONS section is a crucial diagnostic element, featuring a combined chart that visualizes the relationship between Load, Temperature, and Working Hours over time. This visualization helps identify trends, anomalies, and deviations associated with potential component failure (e.g., a sharp temperature rise without a corresponding load increase), ensuring that all tags interact correctly.

Together, these elements deliver a complete operational and diagnostic view of the machine’s health, service status, and performance trend.

Key Benefits

• Instant Motor Health Diagnosis: Rapid identification of potential motor overload or overheating.

• Service Optimization: Automated alerts for mandatory service (Overdue) based on working hours, preventing failures.

• Trend and Correlation Analysis: Understanding the relationships between load, heat, and usage for predictive maintenance.

• Usage Tracking (Pay Per Use): Accurate documentation of total working hours for billing or asset management.

• Anomaly Detection: Pinpointing abnormal performance patterns that suggest developing mechanical or electrical issues.

Core Functionalities

• Motor Load Monitoring: Tracking amperage (Amp) and evaluating actual motor strain.

• Motor Temperature Monitoring: Detecting potential overheating issues.

• Working Hours Calculation: Cumulative tracking of machine operating time.

• Automated Service Scheduling: Determining service need based on accrued working hours.

• Correlation Analysis: Comparing load, temperature, and usage trends over time.

• Historical Performance Analysis: Displaying past trends through daily line charts.