Provide real-time visibility and diagnostic insight into the sealing and gas injection processes of a Vertical Form Fill Seal (VFFS) snack packaging machine. The dashboard monitors critical parameters that directly affect package integrity, product freshness, and line performance

Dashboard Overview

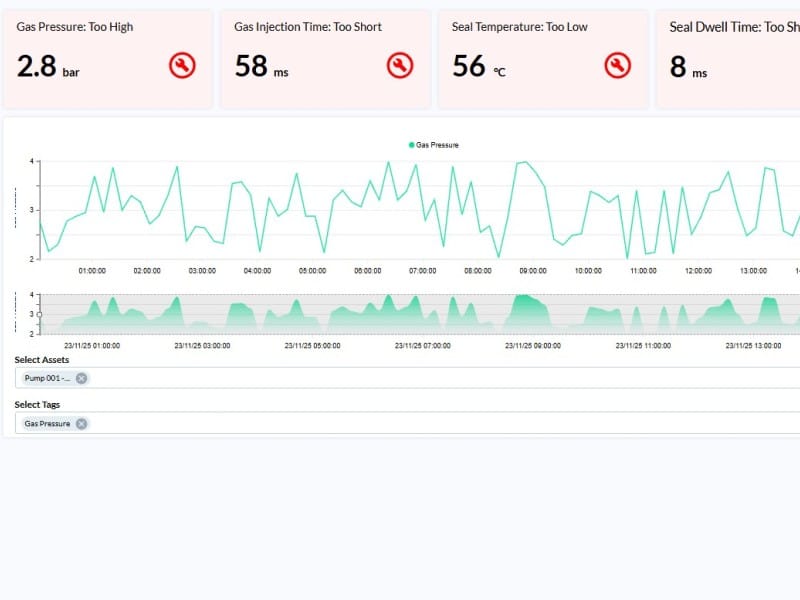

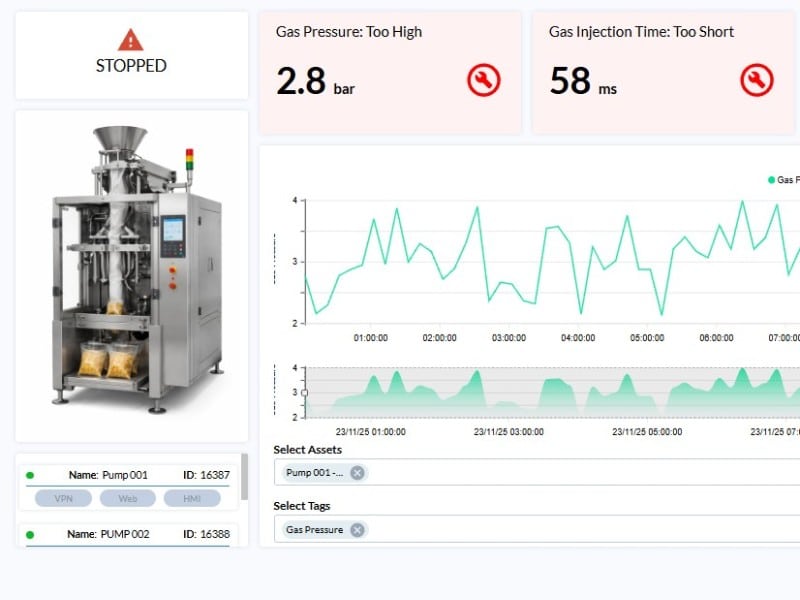

The dashboard opens with a clear status area displaying the selected product configuration and the current machine state. Color-coded status cards immediately highlight abnormal conditions such as excessive gas pressure, insufficient gas injection time, low seal temperature, or insufficient seal dwell time. The colored backgrounds allow operators to quickly recognize degraded or critical conditions without the need for detailed trend analysis.

Key process KPIs display real-time values for Gas Pressure, Gas Injection Time, Seal Temperature, and Seal Dwell Time. Each KPI is evaluated against predefined operating ranges to determine whether sealing conditions are effective for maintaining package integrity and product shelf life.

The main trend section features a correlation line chart that combines all critical sealing and gas parameters on a shared timeline. This visualization allows operators and engineers to observe interactions between variables, identify drift, and detect abnormal patterns such as compensating behavior between temperature and dwell time or unstable gas pressure affecting seal quality.

By filtering or selecting individual tags, users can focus on individual parameters or analyze their combined behavior during slow, degraded, or unstable machine operation. This correlation view supports faster root-cause analysis and process optimization.

Together, the dashboard provides a complete operational and diagnostic view of the VFFS snack packaging process, supporting consistent seal quality, reduced waste, and improved production reliability.

Key Benefits

• Quickly identify degraded or unstable sealing conditions using color-based status indicators.

• Ensure consistent package sealing to protect product freshness and quality.

• Detect abnormal interactions between gas injection and sealing parameters.

• Reduce scrap and rework by addressing issues before seal failure occurs.

Support for continuous process optimization through historical trend and correlation analysis.

Core Functionalities

• Seal Temperature Monitoring: Verifies that sealing heat remains within effective limits.

• Seal Dwell Time Monitoring: Ensures sufficient sealing duration for reliable package closure.

• Gas Pressure Monitoring: Track gas pressure to maintain proper package atmosphere.

• Gas Injection Time Monitoring: Validates correct timing of gas flushing operations.

• Status Visualization: Highlight process health using color-coded KPI cards.

• Correlation Analysis: Analyze combined behavior of sealing and gas parameters over time.