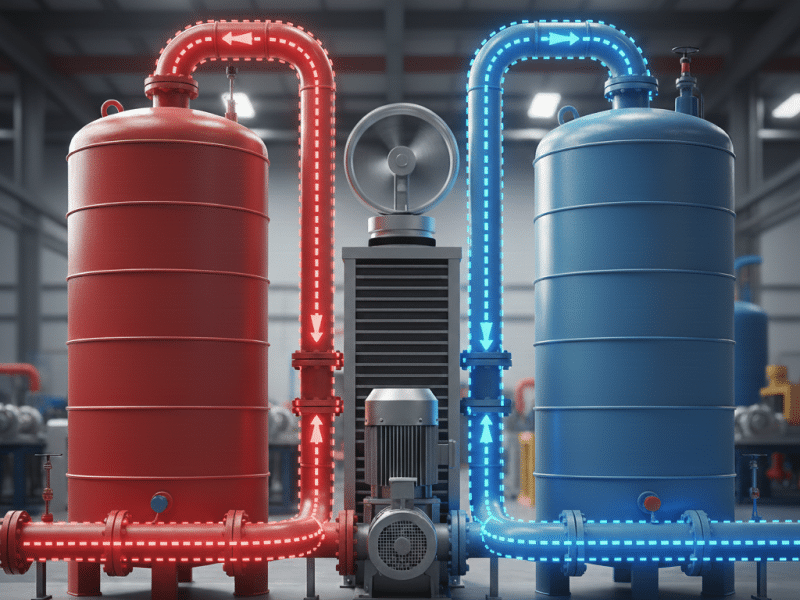

Provide a comprehensive real-time view of a cooling system that absorbs heat, cools process equipment, and returns cooled liquid back to the plant. The dashboard monitors temperature differences, pressure differences, and correlation across key system tags.

Dashboard Overview

The dashboard opens with two diagnostic indicators that evaluate temperature delta and pressure delta. The temperature difference indicates whether heat transfer is operating as expected. A healthy temperature delta confirms that hot water is cooling efficiently before returning to the plant. The pressure difference evaluates possible leaks or flow restrictions. Low or negative pressure delta values may indicate leaks, blockages, or mechanical issues. These two values provide an immediate diagnostic summary of overall cooling health.

Additional gauges display hot water temperature, cold water temperature, inlet pressure, and outlet pressure. These measurements validate whether the cooling loop is delivering the expected thermal and pressure conditions for stable operation.

A correlation chart visualizes the relationship between temperature, pressure, and delta values over time. This visualization helps operators identify trends, anomalies, and deviations associated with leaks, fouling, pump degradation, heat exchanger efficiency loss, or unstable process loads. Selecting specific tags allows deeper comparison between temperature behavior, pressure fluctuations, and flow-related events.

The real-time telemetry table provides a structured history of system readings, including pressure in, pressure out, temperature in, and temperature out. This supports maintenance diagnostics and long-term performance verification.

Together, these elements deliver a complete operational and diagnostic view of a water-based cooling system, enabling fast problem identification, improved reliability, and optimized cooling efficiency.

Key Benefits

• Instantly identify leaks, restrictions, or abnormal heat transfer through delta-based diagnostics.

• Monitor hot and cold water temperatures to ensure the cooling loop is performing correctly.

• Track pressure behavior to detect flow instability and mechanical problems early.

• Analyze temperature and pressure correlations to understand system trends and inefficiencies.

• Use real-time telemetry to support maintenance decisions and root-cause analysis.

Core Functionalities

• Temperature Delta Monitoring: Evaluate heat transfer performance using real-time hot and cold water temperature differences.

• Pressure Delta Monitoring: Detect leaks, restrictions, or pump issues by monitoring pressure difference across the circuit.

• Heat Transfer Gauging: Validate whether hot water is properly cooled before returning to the plant.

• Temperature and Pressure Gauges: Provide clear visual indicators of real-time system state.

• Correlation Analysis: Compare temperature and pressure trends to understand system interactions.

• Real-Time Telemetry: Record and review operating conditions for troubleshooting and performance verification.