Hardware

Unitronics

- Unitronics Building

Haarava 3, Airport City

7019900, Israel - +972-3-9778844

- [email protected]

TG Elektro & Automasjon AS (TG) is a Norwegian electrical/automation engineering and manufacturing company. It is the Company’s mission to help its customers to reduce energy consumption and maintenance costs with condition-based maintenance and plant-customized solutions. The Company provides its engineering control cabinets with total solutions for process and machine control. TG’s advanced Industry 4.0 solution features built-in BI functionality to learn and compare performance. It features fully customizable dashboards to view data for Identifying problems before they occur. This way, the data can be used for preventive maintenance.

One of TG’s customers, Aase Gartneri AS, grows cucumbers in a greenhouse of approximately 17,000 square meters for a cucumber production of about 850 tons per annum. The greenhouse is equipped with environmentally friendly energy sources. The grower was facing high energy consumption costs for growing its cucumbers, which lowered its profitability. TG approached Unitronics to find a way to optimize control parameters for efficient monitoring. It was also crucial to get real-time insights into the dehumidification process by using dashboard parameters. Also, assisting customers and providing secure remote support was a priority.

TG had already extended experience with the Unitronics’ solutions. Since TG knew that UniStream and UniCloud provide good operational regularity, it was a no-brainer to also offer the same to its customer, Aase Gartneri, a cucumber grower. UniStream PLC serves as the main control for the dehumidification units, the 30m3 energy storing tank, mixing and regulation of the irrigation system, the circulation pumps, energy metering, and for the valves.

Using UniCloud, TG wanted to quickly access and control systems and remote alarms, which UniCloud provides. Furthermore, the deployed UniCloud did not only benefit the grower but also the machine builder. All parties involved now have an overview of all the solutions, such as the dehumidification process and the process systems integrated into the same solutions. TG created a total solution that was easy to expand, thanks to UniCloud. The UniCloud connection and dashboard function were set up quickly. This allowed TG to provide secure remote support using comprehensive dashboards and setting up SMS/mail alarms.

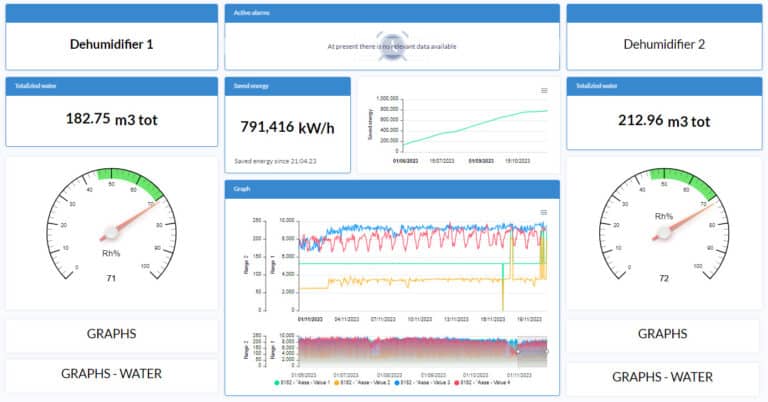

The cucumber grower uses UniCloud’s dashboard for real-time climate status, real-time energy consumption, and energy regeneration values, total volume of separated water from air, historian graphs for energy, and process sensors (which is important for condition-based maintenance and optimization), and VNC remote HMI. The grower also uses the SMS alarm functionality since the cucumbers can be damaged if the climate control or utility process is not functioning properly. Overall, the system sends an alarm if VFDs, remote IO, Modbus for valves, or energy metering devices break down or if one or more sensors are out of range. The system is also set up with cause and effect and will push alarms according to this configuration.

Thanks to the customizable dashboards, it had become easier for TG to manage access for its customers. The dashboard at the cucumber grower is customized to be plant-specific, especially to display energy data and process values. The main system and the VNC (HMI) are also displayed. By opting for Unitronics and UniCloud, it was easy for TG to expand the facility. Currently, most of TG’s customers are running via UniCloud for remote operation support, telemetry, and customer dashboards for getting insights and overviews.

TG was particularly appreciated by the ease of engineering and deployment of UniCloud, especially when paired with Unitronics’ variable frequency drives (VFDs) and IO modules. The VFDs control the fan speed inside the dehumidification units and the flow regulation pump for water-filled systems. This has become really easy thanks to the integrated setup of VFDs in UniLogic. The UniLogic software tool prepares and defines all project-related products, including VFDs, which reduces the engineering time of TG significantly.

In addition, sustainability and environmental issues have a powerful effect on business investment policies. Enterprises that follow ESG regulations and adhere to its compliance criteria are more attractive to investors who are looking for environmentally “green” investments.

A recent McKinsey report presents a case of a chemicals company that took part in the worldwide effort to reduce greenhouse-gas emissions. Over a three-year period, they cut their energy consumption on different sites by 7-13%, in a project which accrued almost $50 million in annual savings.

The implementation of UniCloud, as part of an all-in-one solution, yielded remarkable results.

Thanks to UniCloud, Aase Gartneri AS documented results indicated that the cucumber grower is reducing its total energy consumption by 50%. This translates into savings of more than 1,000,000 kW/each year. This means that the grower’s profitability also increased significantly.

Furthermore, having one integrated solution, comprised of PLC, IO, VFD, and UniCloud, allows TG to control all parameters for optimized operation, achieving:

1. Operational Efficiency. The grower was able to increase the product quality of its cucumbers due to UniCloud, which enables the regeneration of heat for the production of irrigation water.

2. Total Asset Overview. UniCloud provided TG with a systematized total overview of all assets for all customers, enhancing their ability to monitor and manage machines effectively using machine data in real-time and automatic BI tools.

3. Positive Customer Feedback. TG’s customer was especially impressed by the ease of use and customization capabilities of UniCloud. The user-friendliness and flexibility of UniCloud make it easy to get an overview of the entire system in a simple way and to change or customize settings.

Overall, UniCloud gives the operational security and predictability that TG’s customers need.

“It was a no-brainer to deploy UniCloud at our customer Aase Gartneri. Since the end of April until November, this cucumber grower already saved more than 700,000 kW/h in seven months. That’s why I recommend other machine builders to use UniCloud as well, since it is the easiest and cheapest way for modern IIOT solutions.”

Tommy Gjedrem, Founder of TG Elektro & Automasjon AS – Engineering, consultant and operation support